Allt när det gäller stål och metaller

- Enhet

- Antal

-

- Radmärke

Vill du bli kund?

Ansök om kundkontoProduktinformation

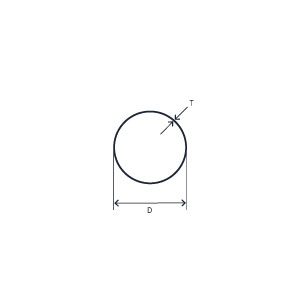

E355 är analysmässigt identisk med S355 men beteckningen ”E” visar att det är fråga om en rörprodukt. Skalade-rullpolerade cylinderrör kan användas direkt i avancerade hydrauliska system som arbetar under högt tryck. Den invändiga rullpoleringen skapar en yta som är väl anpassad för kontakt med hydrauliska tätningar. Första steg i tillverkning av rören är varmvalsning i ett verk för sömlösa rör. Efterföljande kalldragning av rören höjer hållfastheten och förbättrar toleranser. De skalade-rullpolerade cylinderrören har väggtjocklekar upp till 25 mm.

Sömlösa kalldragna rör i stål E355 standardiseras i SS-EN 10305 - 1. Tillägget ”+SR” är indikativt att rören har avspänningsglödgats efter kalldragning. I jämförelse med varmvalsat tillstånd höjer kalldragning stålets sträckgräns som sedan sjunker något till följd av glödgningen till en nivå 520 MPa eller högre i de färdiga rören. Brottgränsen höjs också men inte lika mycket som sträckgränsen och förlängningen blir något mindre till följd av kalldragningen/glödgningen.

Den utvändiga toleransen av skalade-rullpolerade cylinderrören stipuleras i SS-EN 10305 - 1. Invändigt är toleransen H8 som definieras i ISO 286 - 2. Den invändiga ytfinheten uttryckt som Ra är 0,4 µm eller bättre. Rakheten mät som högsta pilhöjd är högst 0,0005 gånger rörets längd.

E355 rören har utmärkt svetsbarhet och stålets kolekvivalent är som högst 0,52 % vilket betyder att förvärmning krävs normalt inte. Dessutom innebär det kalldragna utförandet att maskinbearbetbarheten är allmänt ganska god.